Hydrotechnik 31V7-70-35.030 Flow Turbine

Brand: Hydrotechnik (Germany)

Type: Insertion/online turbine flowmeter

Measurement principle: Mechanical turbine (fluid drives impeller to rotate, magnetic induction detects speed)

Core functions and parameters

1. Mechanical performance

Diameter specification: DN70 (2.5 inches)

Connection method: Flange connection (standard EN 1092-1 or ANSI B16.5, specific confirmation required)

Material:

Housing: stainless steel (1.4404/316L)

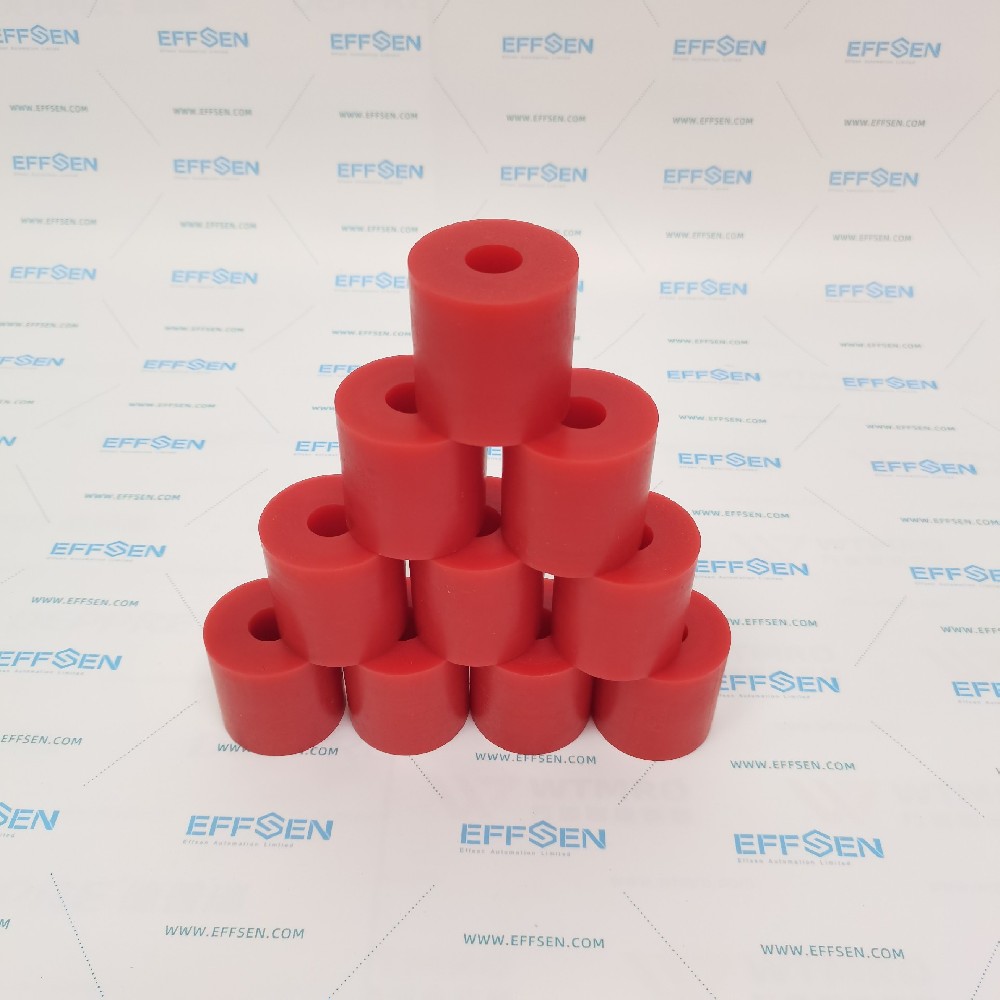

Impeller: PPS or 316L (corrosion resistant)

Bearing: ceramic/tungsten carbide (long life design)

Pressure level: PN16 (standard), optional PN25/PN40

Medium temperature: -20°C to +120°C (high temperature type can reach +150°C)

2. Measurement performance

Flow range:

Water: 5~350 m³/h (typical)

Oil: 3~250 m³/h (depending on viscosity)

Accuracy: ±0.5% reading (after calibration), ±0.2% optional (high-precision type)

Repeatability: ±0.1%

Output signal:

Pulse output: square wave frequency signal (such as 1~1000Hz, K factor adjustable)

Analog output: 4~20mA (optional transmitter module required)

Digital communication: RS485 (Modbus RTU) or HART (optional)

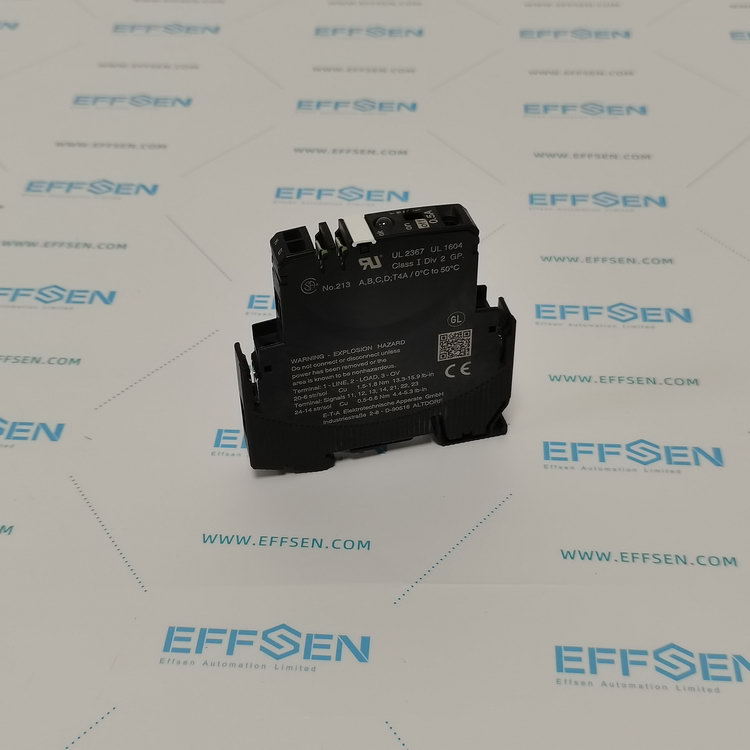

3. Electrical characteristics

Supply voltage: 12~24V DC (pulse type) or 24V DC/220V AC (with transmitter)

Protection level: IP65 (standard), IP68 (optional for submersible type)

Explosion-proof certification: ATEX, IECEx (optional)

Product features

High dynamic response: suitable for fast flow change monitoring (such as hydraulic system)

Low pressure loss: optimized flow channel design, pressure loss <0.2 bar (at full scale)

Bidirectional measurement: supports forward and reverse flow detection (special configuration required)

Self-diagnosis function: impeller jam or empty pipe alarm (intelligent transmitter version)

Typical applications

Industrial processes: chemical medium metering, cooling water circulation monitoring

Energy systems: fuel/lubricating oil flow measurement

Ship: ballast water, fuel consumption monitoring

OEM integration: large equipment flow feedback control