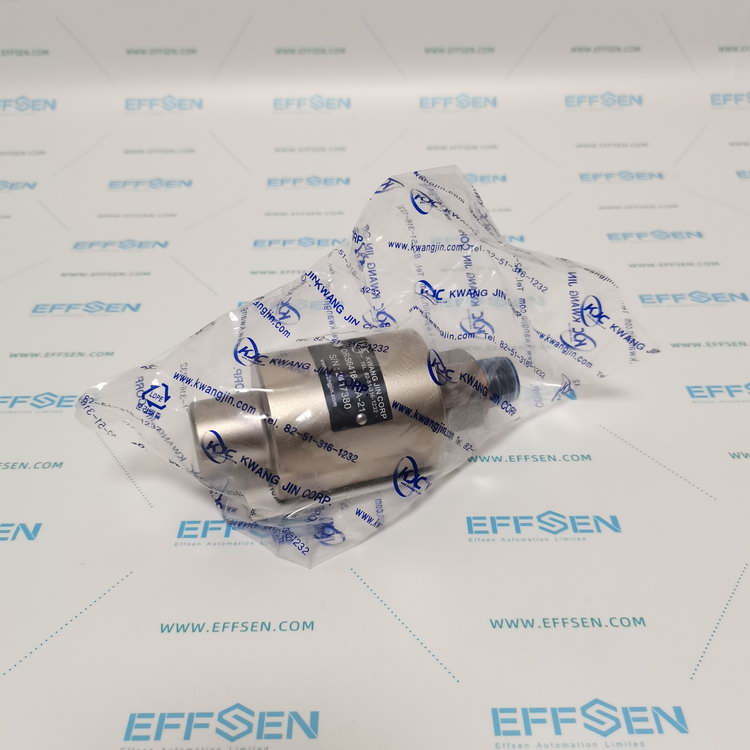

Hydrotechnik 3403-40-I5.37S Pressure Sensor

Product Description

1. Product Overview

Brand: Hydrotechnik

Model: 3403-40-I5.37S

Type: Industrial-grade digital pressure sensor (IO-Link 1.1 version)

Core features: process automation integration + self-diagnosis + ultra-high precision

Typical applications: hydraulic system monitoring, predictive maintenance, Industry 4.0 applications

2. Core technical parameters

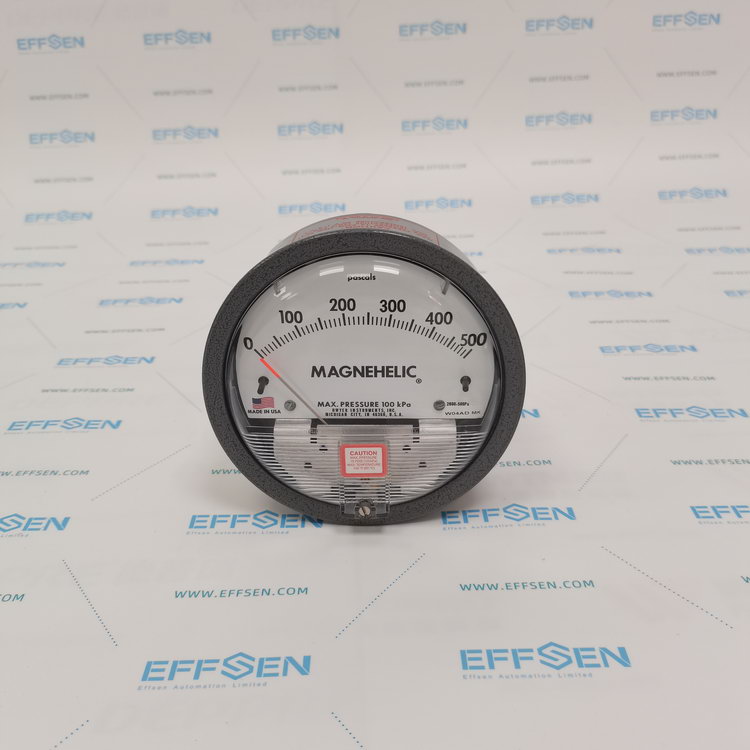

(1) Measurement performance

Range: 0...400 bar (optional 0...40/1000 bar)

Comprehensive accuracy: ±0.1% FS (at 23°C)

Long-term stability: <±0.2% FS/year

Temperature effect: ±0.02% FS/°C (automatic compensation)

Sampling rate: 1 kHz (dynamic pressure capture)

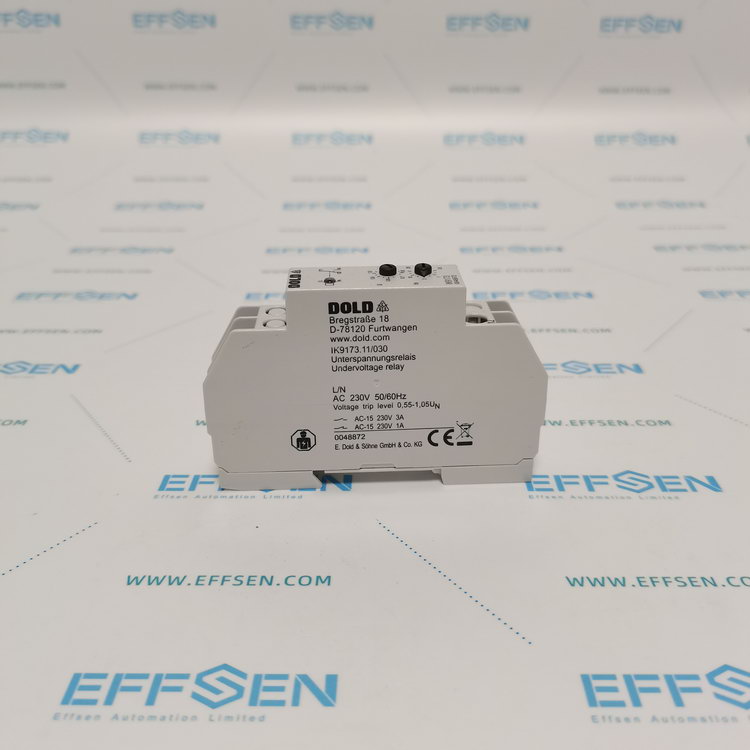

(2) Communication interface

IO-Link:

IEC compliant 61131-9 standard

Real-time transmission: pressure value, temperature, device status

Remote configuration of parameters: range/filter/alarm threshold

Fault protection: 4...20mA analog backup output

(3) Mechanical design

Process connection: G¼" internal thread (ISO 1179-2 standard)

Material combination:

Pressure port: 316L stainless steel (electrolytic polishing)

Diaphragm: ceramic/Al₂O₃ (corrosion-resistant version optional)

Protection level: IP67 (sensor)/IP65 (electrical interface)

3. Intelligent functions

Self-diagnosis system:

Diaphragm integrity monitoring

Signal drift warning (failure prediction 3 months in advance)

Cable break detection

Data logging: cyclic storage of the last 50 pressure peaks

Unit switching: switch bar/psi/MPa by software (retain calibration data)

4. Product advantages

✔ IIoT ready: direct access to PLC/cloud (supports JSON data format)

✔ Anti-interference design: double-shielded cable interface (EMC complies with EN 61326-1)

✔ Zero maintenance: O-ring-free sealing structure (lubrication-free for life)

✔ Quick installation: 360° rotatable electrical interface

5. Typical application scenarios

Intelligent hydraulic station: real-time pressure monitoring + energy efficiency optimization

New energy equipment: closed-loop control of lithium battery press

Semiconductor manufacturing: monitoring of hydraulic system of etching machine

Digital twin: synchronization of physical system and virtual model data