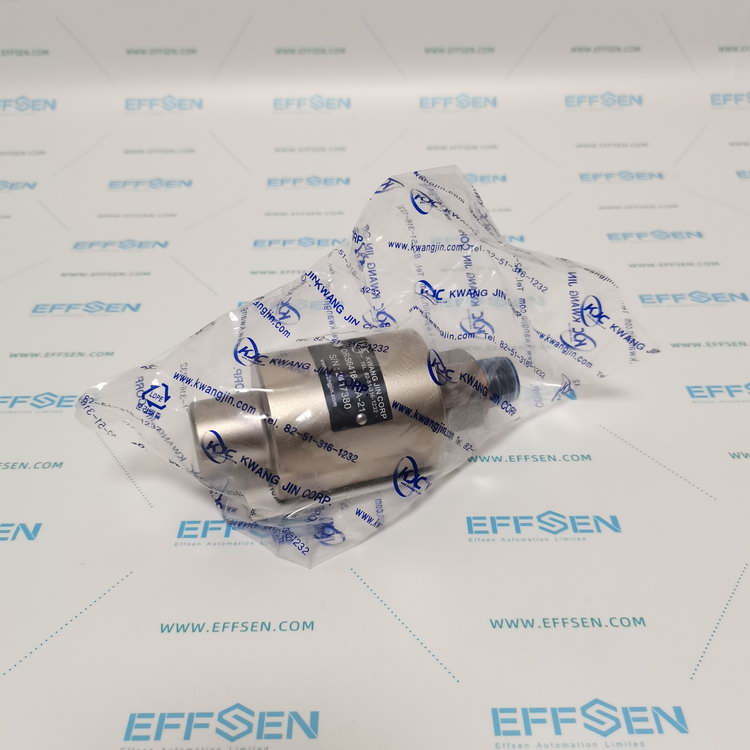

Hydrotechnik RE4-300 31VH-71-35.030 Flow Turbine

Product Description

1. Product Overview

Brand: Hydrotechnik

Model: RE4-300 31VH-71-35.030

Type: Industrial-grade high-precision turbine flowmeter (bidirectional measurement)

Core features: ultra-wide range ratio + high pressure resistant design + digital signal output

Typical applications: hydraulic system flow monitoring, energy management, process control

2. Core technical parameters

(1) Mechanical properties

Diameter specification: DN71 (2.8 inches)

Connection method: flange (EN 1092-1 PN40, optional ANSI B16.5)

Structural material:

Housing: 316L stainless steel (mirror polished flow channel)

Impeller: tungsten carbide bearing + titanium alloy blade

Seal: double PTFE packing (zero leakage)

Pressure rating: 420 bar (static) / 250 bar (working pressure)

(2) Measurement performance

Flow range:

Water: 2...600 m³/h (Reynolds number Re>4000)

Hydraulic oil: 1.5...450 m³/h (viscosity ≤46 cSt)

Accuracy: ±0.3% of reading (after calibration), ±0.15% optional

Repeatability: ±0.1%

Temperature range: -40°C to +150°C (high temperature type up to +200°C)

(3) Signal output

Dual channel output:

Channel 1: frequency pulse (1...10kHz, square wave)

Channel 2: IO-Link V1.1 (including temperature/diagnostic data)

Compatible protocols:

Pulse: compatible with PLC high-speed counter

Digital: Profinet/Modbus RTU (optional module required)

3. Intelligent functions

Self-calibration mode: automatically correct viscosity effects via IO-Link

Flow direction identification: independent accumulation of forward/reverse flow (bidirectional measurement)

Wear warning: maintenance alarm triggered when impeller speed is abnormal

Data logging: built-in storage of the last 100 sets of peak flow

4. Product advantages

✔ Ultra-long life: tungsten carbide bearing design (>100,000 hours MTBF)

✔ Low pressure loss: optimized flow channel design (ΔP<0.15 bar@Qmax)

✔ Ready to use: only 5×DN is required for the front straight pipe section (industry leading)

✔ Multi-media adaptation: oil/water/gas calibration curves can be switched through software