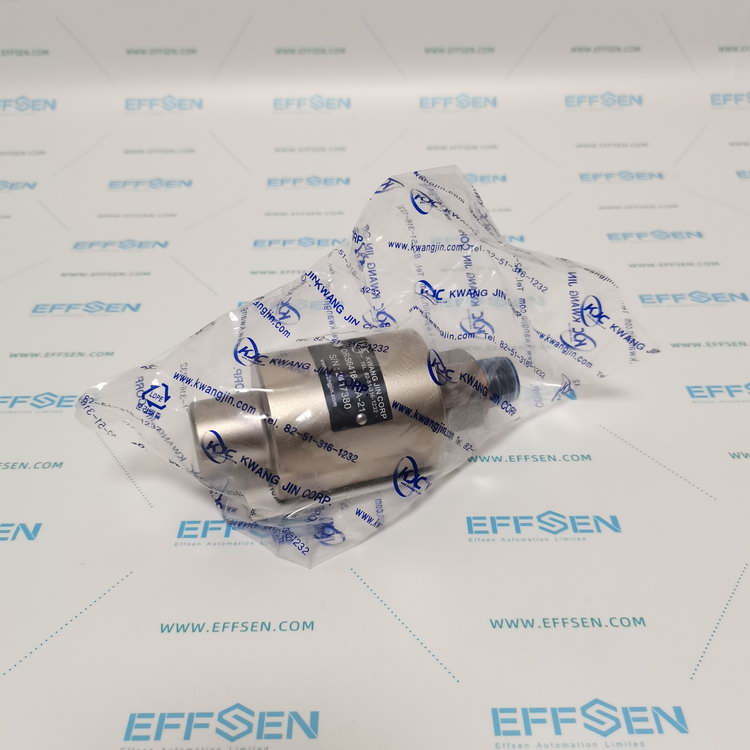

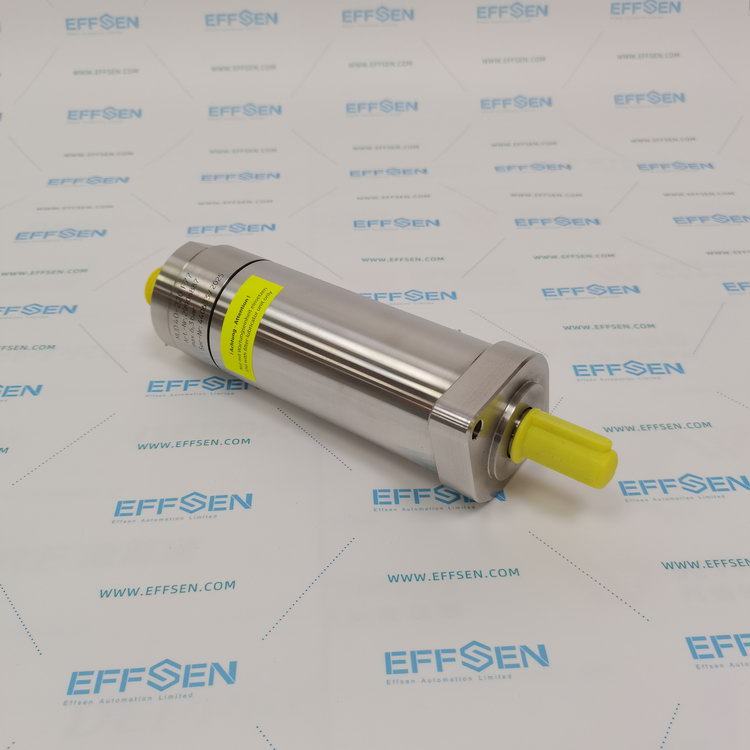

Burkert S030-555346 Fitting inline DN15 SST/paddle wheel PD

Core functions and features

Measurement principle

Paddle wheel (impeller) mechanical sensor, the fluid drives the paddle wheel to rotate, and the speed is proportional to the flow rate

Non-contact magnetic induction detection (Hall effect or magnetic resistance principle), no mechanical wear

Signal output

Pulse signal (frequency output):

Typical output: square wave pulse (such as 1~1000Hz), the corresponding number of pulses per liter is adjustable (K factor calibration)

Compatible with counting devices such as PLC, flow integrators

Optional analog output (need to confirm the model suffix): 4~20mA (corresponding to the flow range)

Mechanical parameters

Installation method: online threaded connection (G½", NPT½", etc.) or flange type (need to be confirmed)

Pressure rating: PN16 (standard), higher pressure needs to be customized

Medium temperature: -10°C to +100°C (standard, high temperature optional)

Electrical parameters

Supply voltage: 5~24V DC (pulse output type)

Load capacity: ≤20mA (NPN/PNP output)

Protection level: IP65 (sensor head)

Technical parameter table

Project parameters

Measuring range: Water: 0.3~6 m/s (typical), depending on the viscosity of the medium

Accuracy: ±1% reading (after calibration, water medium)

Repeatability: ±0.5%

Wetted parts: Paddle wheel: 316L stainless steel / Shaft: Ceramic / Seal: FKM or EPDM (optional)

Media compatibility: Water, low viscosity oil, coolant, etc. (not suitable for high viscosity or solid particle containing media)

Pressure loss: <0.1 bar (at maximum flow)

Product features

Compact structure: DN15 small diameter design, suitable for space-constrained pipeline installation

Low flow sensitivity: Optimized paddle wheel design, can detect small flow (minimum 0.3 m/s)

Passive type optional: no power supply required, only mechanical pulse output (magnetic induction)

Typical applications

Industrial circulating water: cooling system flow monitoring

Lubrication system: oil flow detection

Laboratory equipment: small pipeline liquid metering

OEM integration: as a low-cost flow detection module

Selection notes

Media requirements: suitable for clean liquids, if containing particles, a pre-filter is required

Flow direction mark: during installation, ensure that the arrow direction is consistent with the fluid flow direction