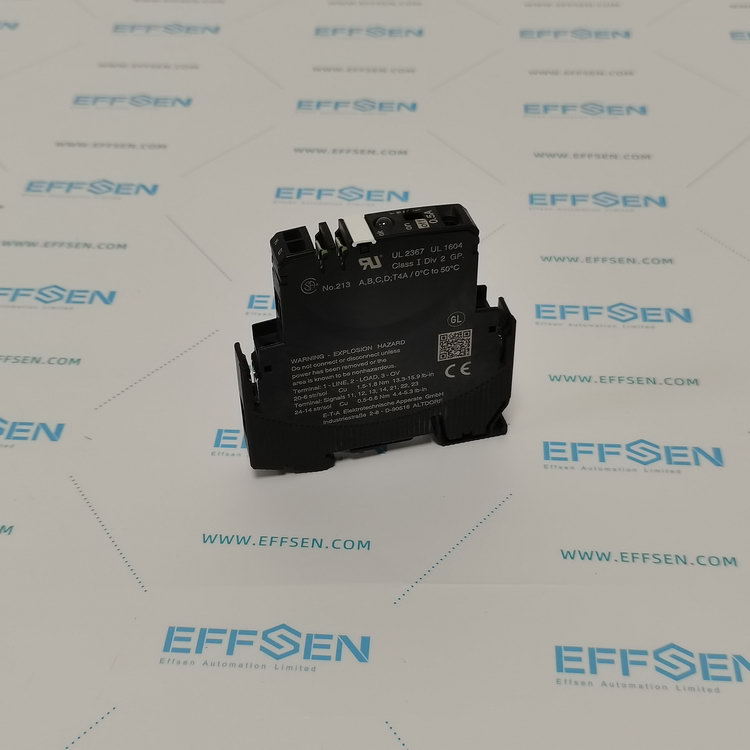

Burkert SE32-560547 Inline flow switch with display

Core functions

Flow measurement and display

Measuring principle: Based on thermal or mechanical (depending on the model) flow sensing technology.

Measuring range: Depends on the medium and pipe size

Display: Integrated LCD display, real-time display of flow value (unit optional: L/min, GPM, etc.).

Switch output

Relay output: 1~2 programmable relays (SPDT or NO/NC) for flow over-limit alarm or pump/valve control.

Set point adjustment: The trigger threshold can be set by key or communication interface (such as action when the flow is lower/higher than the set value).

Signal output (optional)

Analog output: 4~20mA or 0~10V (corresponding to the flow value, need to confirm the model suffix).

Digital communication: Some models support RS485 (Modbus RTU) or fieldbus.

Other functions

Temperature display (if integrated temperature sensor).

Self-diagnosis: sensor failure or pipeline empty pipe alarm.

Technical Parameters

Project Parameters

Media: Liquid (water, oil, chemical liquid, etc., compatibility needs to be confirmed)

Pipe size: DN8~DN50 (or 1/4"~2"), depending on the model

Material: Wetted parts: stainless steel (316L), PPS, PVDF, etc. (corrosion-resistant options)

Pressure range: 0~16 bar (standard), higher pressure requires special models

Temperature range Medium temperature: -10°C to +90°C (standard)

Power supply: 24V DC or 100~230V AC (depending on the model suffix)

Protection level: IP65 (panel)/ IP67 (sensor part)

Installation method: In-line thread (G½", NPT, etc.) or flange connection, low straight pipe section requirement

Features and advantages

Plug and play: No external flow meter required, directly installed in the pipeline.

High accuracy: Thermal principle is sensitive to low flow (can measure small flow changes).

Multi-function display: Simultaneously displays flow, temperature, relay status.

Corrosion-resistant design: Suitable for chemical media (optional PTFE seal or Hastelloy electrode).

Low maintenance: No moving parts (thermal model), high long-term stability.