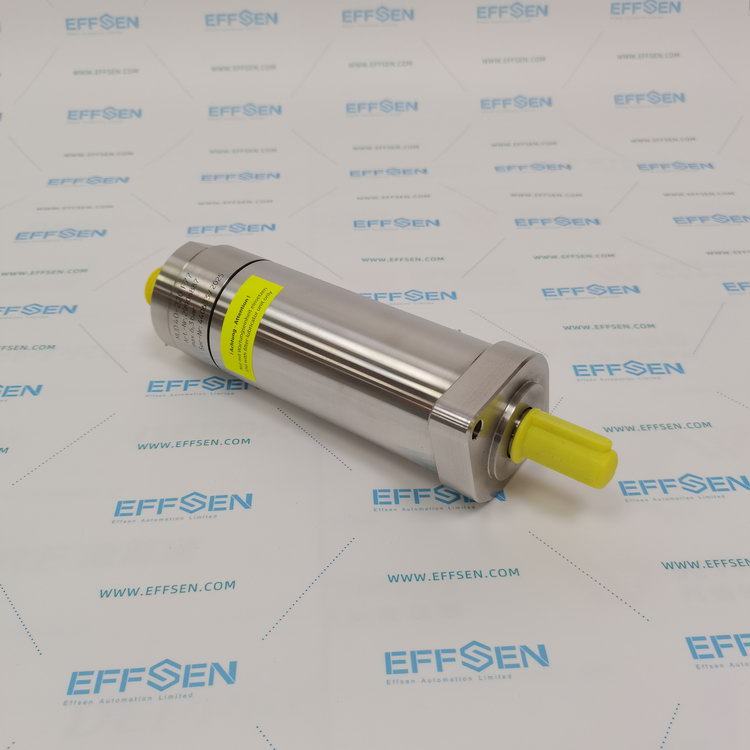

Burkert 8222-562503 Conductivity-transmitter

Core functions

Conductivity measurement

Measuring range: 0~2000 µS/cm (the specific range is adjustable, depending on the electrode configuration).

Accuracy: ±1% FS (full scale).

Temperature compensation: built-in PT1000 temperature sensor, automatically compensates for the influence of medium temperature on conductivity.

Signal output

Analog output: 1 channel 4~20mA (isolated, load ≤500Ω), corresponding to conductivity or temperature value.

Digital communication: RS485 (Modbus RTU protocol) or fieldbus (such as PROFIBUS DP) can be selected.

Control function

2 relay outputs (can be set to high and low alarms, pump control, etc.).

Support threshold alarm (trigger when conductivity exceeds the limit).

Display and operation

Backlit LCD display, real-time display of conductivity, temperature, and alarm status.

Key programming or remote configuration through the communication interface.

Technical Parameters

Project Parameters

Power supply: 24V DC ±10% or 100~230V AC (depending on model suffix)

Power consumption: ≤5W

Protection level: IP65 (panel) / IP67 (housing), suitable for wet or dusty environments

Medium temperature: -10°C to +80°C (standard electrode)

Ambient temperature: -20°C to +60°C

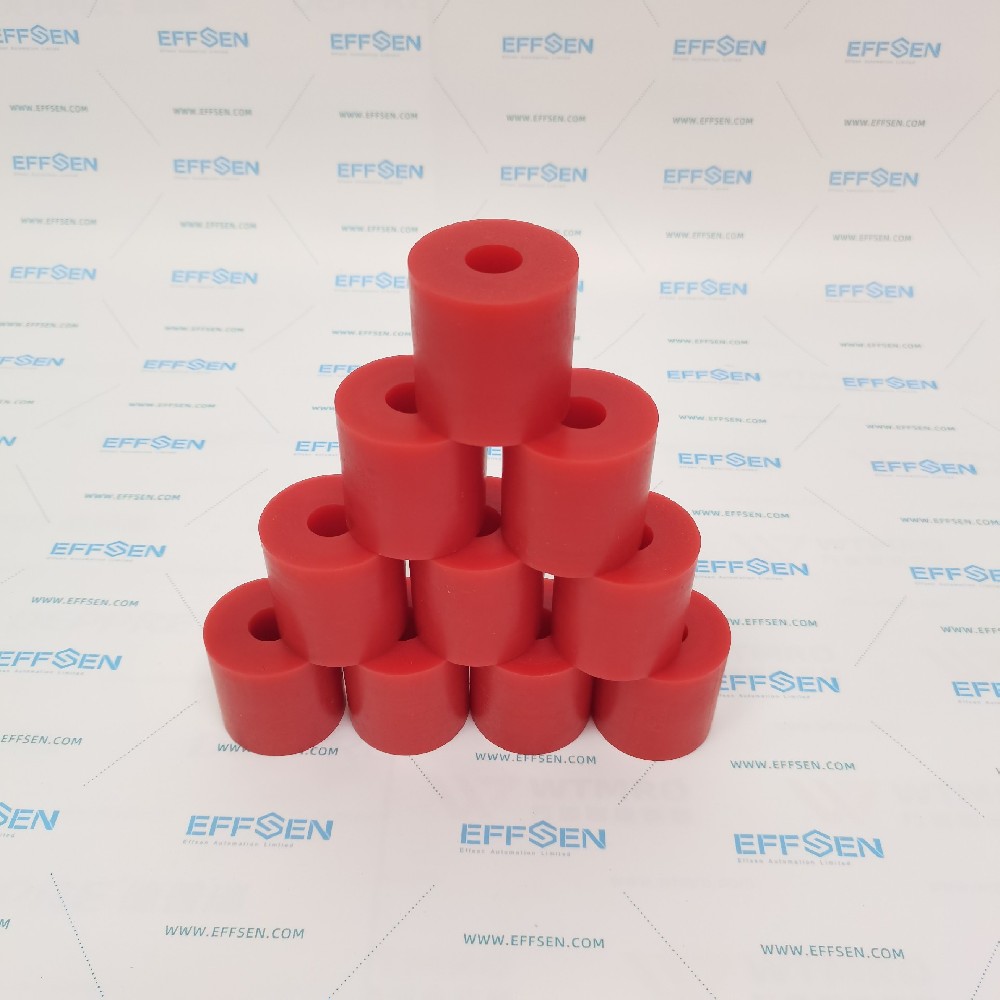

Electrode interface: Support Bürkert ECS series conductivity electrodes (such as ECS-1.0/10.0, etc.) need to be ordered separately

Installation method: wall-mounted or DIN rail mounted (35mm)

Process connection: The electrode is installed through G½" thread or flange, and the transmitter and electrode are separated

Features and advantages

Modular design: compatible with a variety of electrodes, adapting to different ranges and media (pure water, acid and alkali solutions, etc.).

Strong anti-interference: isolated signal output, reducing the impact of electromagnetic interference in industrial environments.

Easy maintenance: The electrode can be removed for cleaning/replacement, and the transmitter parameters are password protected.

Industry compliance: in compliance with CE, UL and other certifications, suitable for food, pharmaceutical, and chemical industries (materials can be selected as 316L or PPS).

Typical applications

Water treatment: reverse osmosis (RO) system, ultrapure water monitoring.

Chemical industry: acid and alkali concentration control, reactor medium monitoring.

Food and beverage: CIP cleaning conductivity detection, liquid concentration management.