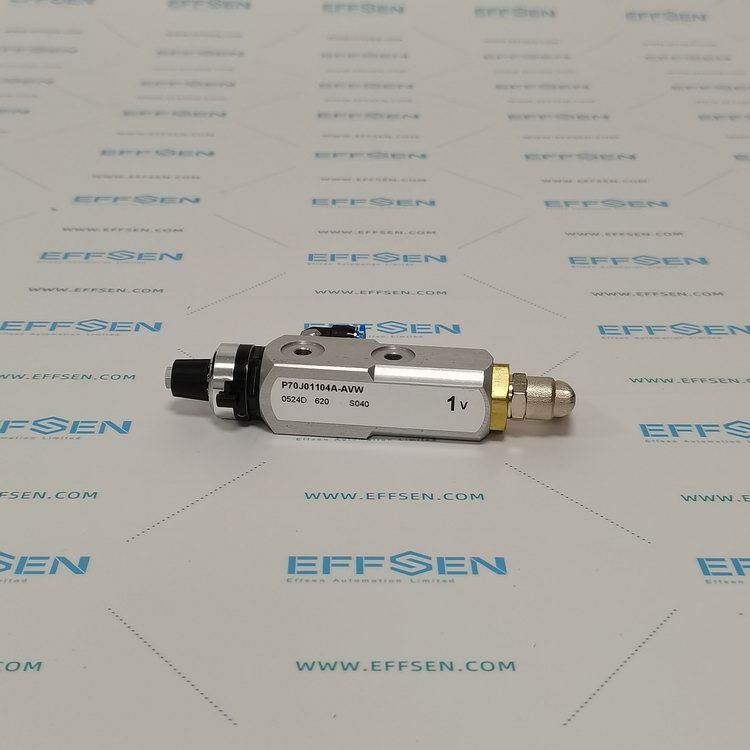

Hydac EDS 344-2-040-000 Electronic Pressure Switch

It is a high-performance electronic pressure switch designed for industrial automation and hydraulic systems. The product combines pressure monitoring and digital display functions, can accurately detect system pressure and provide real-time feedback, and is suitable for a variety of industrial application scenarios.

Technical parameters

Pressure range: 0 to 40 bar (specific range may vary depending on configuration)

Accuracy: ±0.5% FS (full scale accuracy)

Output signal:

Switch output: 2 PNP or NPN optional, load current up to 1.2A

Analog output: 4-20mA or 0-10V (optional)

Display: 4-digit digital display, supports multiple unit switching (such as bar, psi, MPa)

Electrical connection: M12×1 plug, in accordance with IP67 protection grade

Operating temperature: -25°C to +80°C (ambient temperature)

Media temperature: -20°C to +80°C

Protection grade: IP67 (dustproof and waterproof)

Certification: Complies with international standards such as CE, RoHS

Product features

High precision and stability: thick film ceramic sensing technology is used to ensure long-term reliability and accuracy.

Multi-function display: supports real-time pressure value, peak value, switch point and other parameter display, which is convenient for monitoring and debugging.

Flexible configuration: Through key programming, parameters such as switch point, delay, output mode (normally open/normally closed) can be adjusted independently.

Self-diagnosis function: Built-in diagnostic interface, compliant with DESINA® specifications, can detect errors and display "ERROR" information.

Convenient installation: Dual-axis rotation design, optimized display position; threaded interface (such as G1/4) adapts to various installation requirements.

Strong anti-interference ability: Suitable for harsh industrial environments, such as hydraulic oil, water glycol and other media.