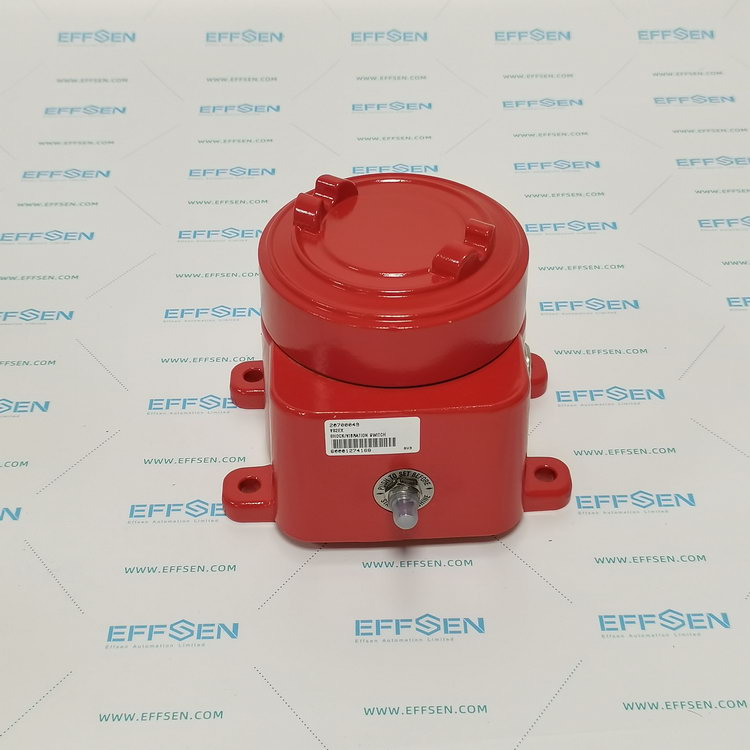

Hydac 0660 R 010 ON Filter element return

Technical parameters

Filtration accuracy: 10μm

Filter material: non-composite glass fiber filter material, high strength, large dirt holding capacity

Structural form: folded filter element, inner support net is 1.5mm thick spiral welded round hole net

Working temperature range: -30℃ to +110℃

Maximum working pressure difference: 0.35MPa

Applicable media: mineral oil, water glycol, emulsion, etc.

Sealing material: nitrile rubber (NBR), optional fluororubber (FPM)

Protection level: IP65 (sensor protection level)

Product features

High-efficiency filtration: glass fiber filter material provides high dirt holding capacity, effectively intercepts tiny particles, and protects the hydraulic system.

Pressure resistance and corrosion resistance: 1.5mm thick inner support net ensures that the filter element does not deform under high pressure, and fluororubber seal is optional to adapt to corrosive media.

Wide temperature application: wide working temperature range, adaptable to harsh environment.

Bypass valve design: when the filter element is blocked, the bypass valve automatically opens to ensure continuous operation of the system.

Easy to maintain: The filter element can be reused after cleaning to reduce the cost of use.

Application areas

Industrial hydraulic system: used for oil circuit protection of hydraulic stations, rolling mills, injection molding machines and other equipment.

Energy equipment: hydraulic oil cleaning of wind power and thermal power systems.

Chemical industry: phosphate ester hydraulic oil filtration (fluorine rubber seal required).

Engineering machinery: hydraulic system filtration of excavators, cranes, etc.

Installation and maintenance

Installation location: usually installed in the return oil pipeline of the hydraulic system.

Replacement cycle: According to the degree of system contamination and working conditions, it is recommended to replace it every 6-12 months.

Maintenance tips: Check the filter element pressure difference regularly, and replace it in time when the pressure difference reaches 0.35MPa.