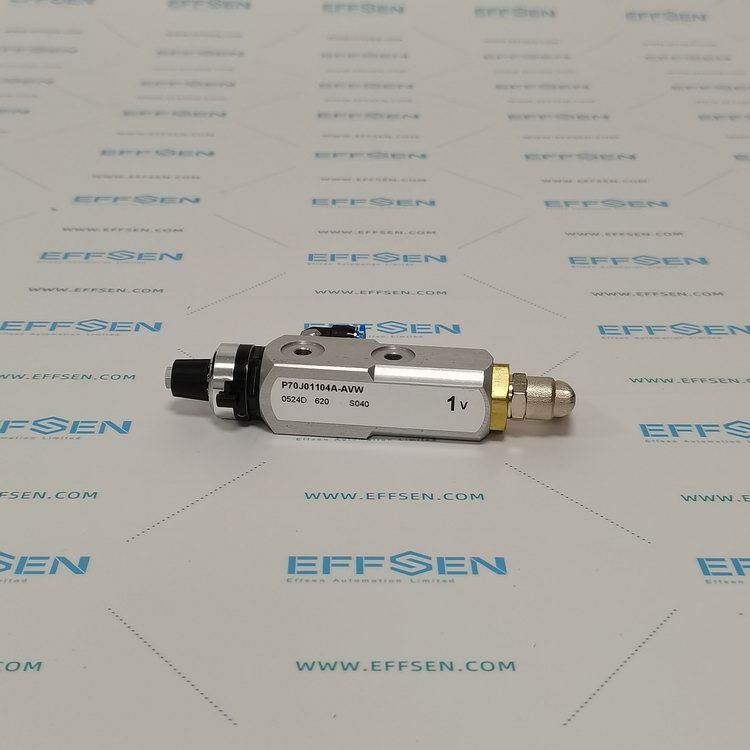

EFFBE MHA100 Diaphragm Pressure Cylinder

Product Features

Diaphragm technology

Core design: The highly flexible elastomer diaphragm has excellent pressure and tear resistance, ensuring that it can maintain sealing after long-term continuous operation.

Functional advantages: The diaphragm structure allows the cylinder to operate accurately and reliably at a pressure difference of 0.01 to 10 bar without stick-slip effect, which is suitable for sensitive control processes.

Oil-free lubrication design

Maintenance-free: The cylinder has a simple structure and does not require grease or oil lubrication, reducing maintenance costs and environmental pollution.

Environmental adaptability: It can maintain stable performance even under extreme environmental conditions (such as high temperature, low temperature or high humidity).

High-precision control

Pressure regulation: As a sensitive pressure regulator, the MHA100 can operate accurately and reliably at a pressure difference of 0.01 to 10 bar, avoiding stick-slip effect.

Application scenarios: Suitable for positioning, clamping, chuck or pressing during the cycle process, etc., where precise force control is required.

Sturdy and durable

Material selection: The housing is made of aluminum alloy and the surface is powder coated to enhance corrosion resistance.

Piston rod: Made of stainless steel, the guide sleeve has its own lubrication function to ensure long-term use without wear.

Technical parameters

Model: MHA100

Type: Piston cylinder (diaphragm structure)

Maximum stroke: 50 mm

Maximum pressure: 10 bar

Ambient temperature: -20°C to +80°C

Air consumption per stroke (6 bar): 0.1 to 0.6 liters

Maximum stroke frequency: 100 times/minute

Weight: about 1.3 kg

Installation method: Flange installation (F) or stud installation (S)

Application areas

Industrial automation: robots, CNC machine tools, precision measuring equipment

Packaging machinery: packaging and sorting systems that require precise control

Automotive industry: process links on the production line that require stable pressure control

Energy field: gas pressure regulators, diaphragm pumps and other equipment

Medical equipment: surgical robots, precision instruments, etc.