Elektror RD10 Side channel blowers

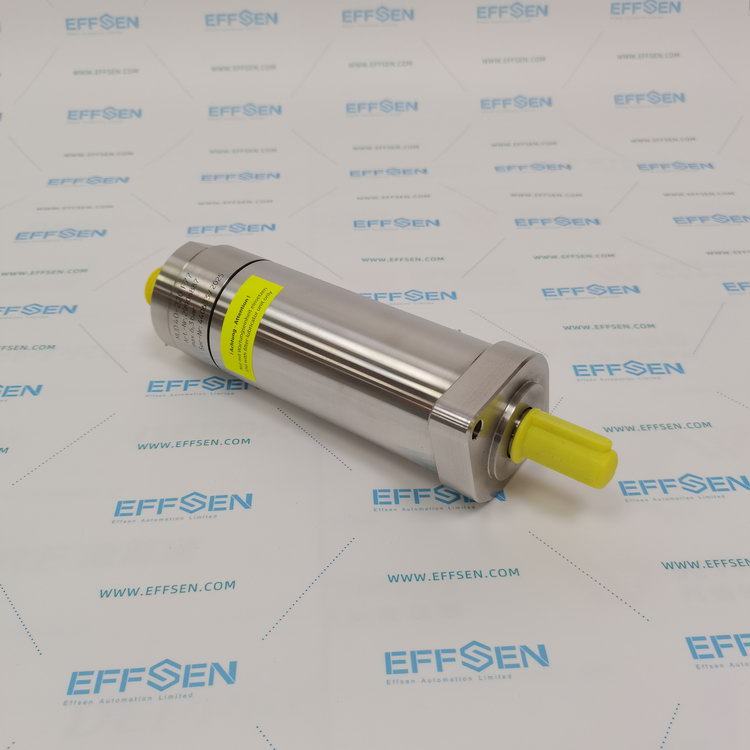

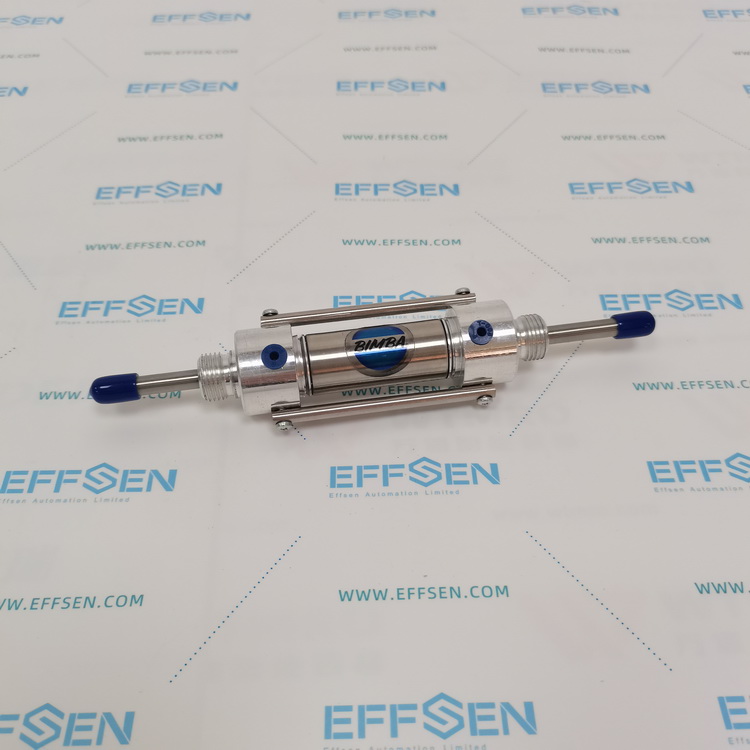

It is a professional equipment designed by the German Elektror brand for high-pressure and medium-flow applications. This series of fans is based on the principle of side-channel compressors. Through unique aerodynamic design, it achieves efficient gas compression and transportation in a compact volume. It is widely used in industrial vacuum, pneumatic transportation, environmental protection equipment and other fields.

1. Core parameters:

Model: RD10 series (such as RD10-XX, the specific model depends on the configuration)

Pressure difference: It can generate a differential pressure of up to 850 mbar (85,000 Pa) to meet high pressure requirements.

Volume flow rate: Up to 1,500 m³/h, suitable for medium-flow application scenarios.

Power range: Depending on the model, the power ranges from 1.5 kW to 7.5 kW to ensure the adaptability of systems of different sizes.

Voltage: Supports 230V/400V dual voltage, frequency 50Hz/60Hz, and adapts to global power standards.

Speed: The maximum speed can reach 3,000 r/min, providing efficient gas delivery capacity.

Material: The housing is made of aluminum alloy or stainless steel, and the key components are specially coated to ensure corrosion resistance and durability.

Protection level: Usually IP55 or higher, with excellent dust and water resistance, suitable for harsh industrial environments.

2. Product features:

High pressure generation: Through the side channel compressor principle, the air is squeezed outward by centrifugal force when the impeller rotates, and is compressed again through the side channel reflux to achieve secondary compression, thereby generating a high pressure difference.

Compact design: The structure is compact and the footprint is small, which is easy to install and integrate into the existing system, especially suitable for space-constrained scenarios.

Low noise operation: The impeller design and housing sound insulation structure are optimized, and the operating noise is less than 75 dB(A), which is suitable for places with strict noise requirements.

Frequency conversion compatibility: Supports speed adjustment through the frequency converter to achieve precise control of air volume and pressure, while achieving energy saving and reducing operating costs.

Corrosion resistance: The housing and key components are made of stainless steel or specially coated to adapt to humid and corrosive environments and extend the service life of the equipment.

Easy maintenance: The modular design facilitates the quick replacement of worn parts and reduces maintenance costs and time.