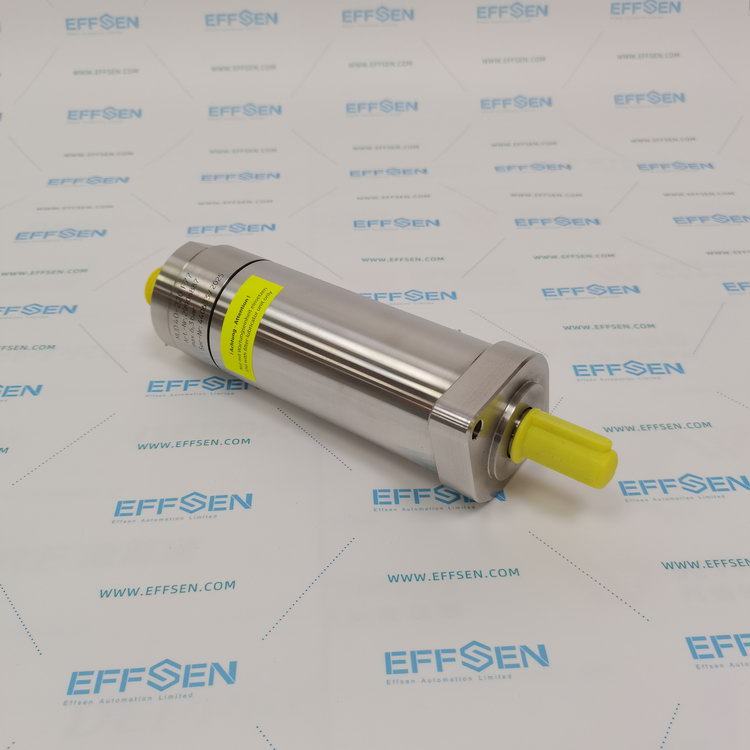

The Tival 1100722 is a rugged IP67-rated inductive proximity sensor with 8mm stainless steel sensing range, NPN/PNP dual output, M12 quick-disconnect connector, and EMC-shielded housing, engineered for harsh industrial environments (e.g., metalworking, automation) to detect ferrous targets reliably up to 8mm with high immunity to noise, vibration, and moisture.

I. Core Detection Specifications

Sensing Distance: 8 mm (standard range for ferrous targets); adjustable for non-ferrous metals (e.g., copper, aluminum) with calibration compensation.

Output Modes: Dual NPN/PNP switchable, compatible with PLCs, relays, and other industrial control interfaces.

Response Time: ≤0.5 ms, optimized for high-speed production lines (e.g., packaging machinery, automated assembly).

Repeatability Accuracy: ±1% of sensing distance, ensuring long-term operational stability.

II. Electrical & Interface Features

Supply Voltage: 10–30 V DC (wide-range tolerance for industrial power fluctuations).

Current Consumption: ≤15 mA (no-load), low-power design extends device lifespan.

Connector Type: M12 quick-disconnect (IP67-rated), supports customizable 3m/5m cables for simplified field wiring.

Status Indicators: Dual-color LED (red/green) for real-time power-on/detection feedback.

III. Environmental Adaptability

Protection Rating: IP67 (dust-tight, waterproof immersion), operational in -25°C to +70°C environments for outdoor or humid applications.

Interference Immunity:

EMC Compliance: Meets EN 60947-5-2 standards, resistant to RFI and EFT disturbances.

Mechanical Shock Resistance: 100g/6ms (half-sine wave), suitable for high-vibration scenarios (e.g., stamping equipment).

Chemical Corrosion Resistance: 304 stainless steel housing withstands oil, acids, and alkalis.

IV. Installation & Commissioning

Mounting Options: Non-flush installation via M18 thread or flat surface mounting, compatible with diverse mechanical structures.

Sensitivity Adjustment: ±10% sensing distance fine-tuning via built-in potentiometer, eliminating need for external controllers.

Reverse Polarity Protection: Internal diode prevents component damage from reversed power supply.

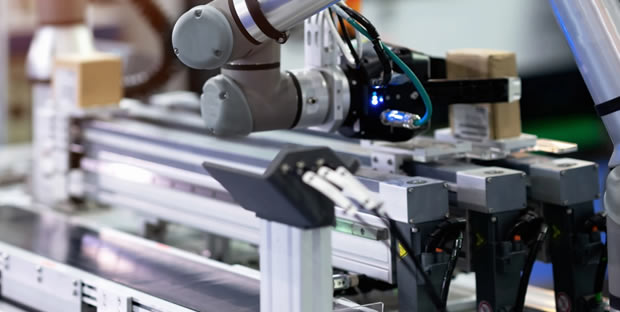

V. Typical Applications

Automated Production Lines: Metal workpiece positioning and counting (e.g., automotive component sorting).

Heavy Machinery: Hydraulic cylinder piston position detection (high-pressure/impact-resistant).

Food Processing: Stainless steel housing meets hygiene standards for detecting metal packaging integrity.

Logistics & Warehousing: AGV collision avoidance detection (ultra-fast response prevents collisions).

VI. Certifications & Compliance

Safety Certifications: CE, UL, cUL, adhering to EU and North American industrial safety norms.

RoHS Compliance: Lead-free manufacturing, environmentally compliant.