Zuwa UNISTAR 2001-A Impeller pumps

1.Product Overview:

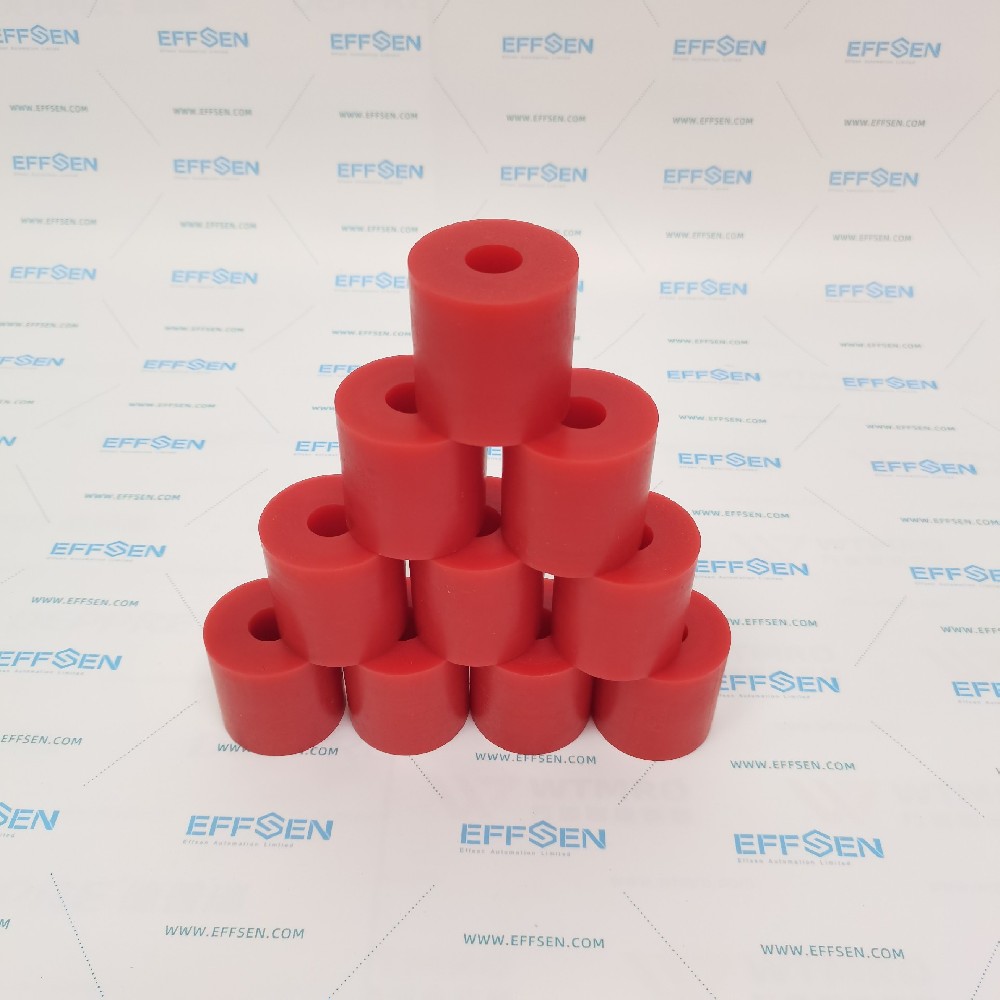

ZUWA UNISTAR 2001-A is an impeller pump produced by ZUWA-ZUMPE of Germany. It is designed for short-term delivery of various liquids and is widely used in chemical, petrochemical, coating, daily chemical, emulsion, ceramic, mining, water treatment, food and beverage, medicine, papermaking, electronics, textile, construction, automobile, furniture, metallurgy and other fields. Made of high-quality materials, the pump has the characteristics of easy operation, low maintenance cost and high reliability, and is deeply trusted by customers.

2. Technical parameters:

Flow range: 15-60 LPM (liters/minute)

Power: 0.75 kW

Maximum pressure: 5 bar

Maximum temperature: 90°C

Self-priming height: 7 meters

Power type: AC/DC dual-use, voltage range 1V-400V (depending on configuration)

Viscosity adaptability: Can handle fluids with viscosities up to 20,000 centipoise, including low-viscosity diesel and high-viscosity antifreeze.

Particle conveying capacity: It can convey suspended hard and soft particle media without damaging the pump body and the media.

3. Functional features:

Strong self-priming ability: Dry self-priming pump, self-priming depth can reach 5 meters of water column, no need for pre-filling when the suction depth is 3 meters, and only simple pre-filling is required at 7 meters to work.

Wide viscosity adaptability: Suitable for a variety of liquids, including diesel, antifreeze (containing additives such as ethylene glycol, propylene glycol) and heating liquids (such as water, ethylene glycol mixture).

Gas-liquid processing capacity: It can convey gas-containing liquid and foam liquid without gas blockage, and is suitable for gas-containing or foam-prone liquid scenes.

Corrosion resistance and wear resistance: Suitable for non-abrasive and non-corrosive media, it is necessary to ensure that the pump body is compatible with the conveying liquid to avoid chemical reactions or corrosion.

Easy to operate: Simple design, easy to install and maintain, and reduce the cost of use.