Steidle S477066 Pneumatic pump

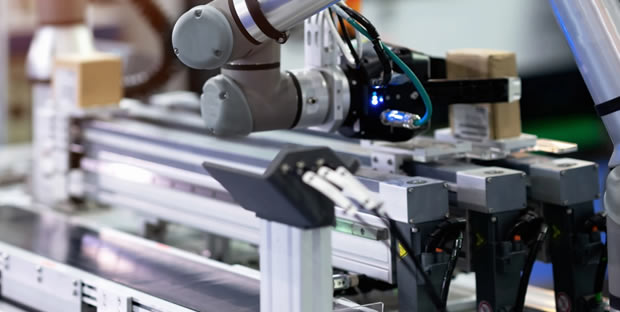

Designed for industrial lubrication, spraying, cooling and other application scenarios, it is widely used in machinery manufacturing, automotive industry, energy equipment and other fields.

Product Features

High Precision and Stability

The plunger pump design ensures that the lubricant is delivered at precise dosages and time intervals, reducing lubricant waste and improving equipment operation efficiency.

Supports the micro-lubrication (MQL) mode, which can achieve the minimum amount of liquid spraying during the processing process, suitable for metal processing, gear transmission and other scenarios.

High Pressure Resistance and Durability

The pump body is made of high-strength aluminum alloy, with a sturdy structure and suitable for high-pressure conditions (maximum working pressure can reach 60 bar).

Built-in wear-resistant components to extend service life and reduce maintenance costs.

Pneumatic Drive and Energy Saving

Driven by compressed air, no electricity is required, suitable for explosion-proof or power-free environments.

Low energy consumption design reduces energy consumption and reduces operating costs.

Modularity and Flexibility

Supports a variety of installation methods and can be directly connected to motors, reducers, etc.

Provides a variety of interface specifications, compatible with existing industrial systems, and reduces integration costs.

Intelligent control

Optional controller to achieve lubrication cycle setting, fault monitoring and nozzle post-blowing function.

Support remote monitoring and automatic control to improve production efficiency.

Technical parameters

Drive mode: pneumatic

Material: aluminum alloy pump body, stainless steel internal components

Working pressure: up to 60 bar

Working temperature: -20°C to +120°C

Flow range: adjusted according to speed and medium viscosity (please refer to the product manual for details)

Applicable media: lubricating oil, coolant, cleaning agent, etc.