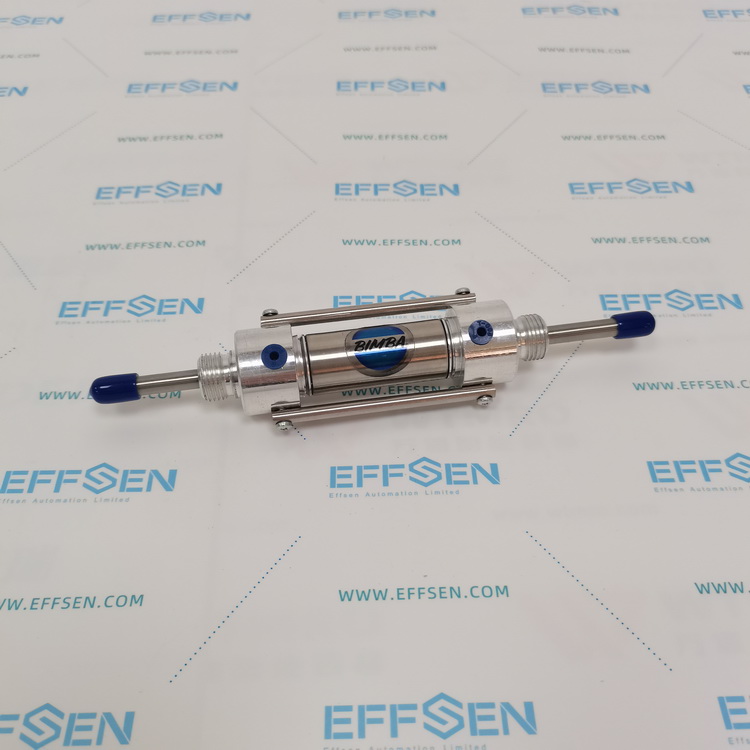

Rickmeier R46/160 FL-Z-W-SAE2.1/2-R gear pump

It is a high-performance gear pump designed for industrial hydraulic systems and suitable for high-pressure and high-flow applications. This product inherits the innovative technology of the Rickmeier brand in the field of gear pumps, and has the characteristics of high efficiency, reliability and durability. It is widely used in engineering machinery, ships, metallurgy, energy and other industries.

Technical parameters

Displacement: 160 cm³/rev

Maximum working pressure: 250 bar

Maximum speed: 3,000 rpm

Viscosity range: 5~2,000 mm²/s

Medium temperature range: -20°C to +120°C

Installation method: SAE standard flange installation (SAE 2.1/2 inches)

Rotation direction: Reversible (bidirectional rotation)

Sealing material: FKM (fluoro rubber)

Shaft seal type: mechanical seal (optional packing seal)

Product features

High-efficiency design: Adopting optimized gear geometry and precision processing technology to ensure high volumetric efficiency and reduce energy loss.

High reliability: Long bearing life, design life of more than 10,000 hours (continuous operation).

Wear-resistant materials (such as hardened gears and wear-resistant sleeves) adapt to harsh working conditions.

Built-in pressure balance structure reduces axial force and extends bearing life.

Low-noise operation: high gear meshing accuracy, smooth operation, and noise below 70 dB(A).

Wide viscosity adaptability range: suitable for media with low viscosity (such as mineral oil) to high viscosity (such as hydraulic oil) to meet the needs of different working conditions.

Compact structure: compact design, small installation space, easy integration into existing hydraulic systems.

Modular design: supports a variety of mounting flanges and shaft seal configurations, which can be customized according to customer needs.

Application areas

Construction machinery: hydraulic excavators, cranes, rollers, etc.

Shipbuilding and marine engineering: steering gear systems, hydraulic deck machinery.

Metallurgy and mining: rolling mills, crushers, conveyor belt drives.

Energy industry: hydraulic systems of wind turbines, hydropower equipment.

Industrial automation: injection molding machines, die-casting machines, metal forming equipment.