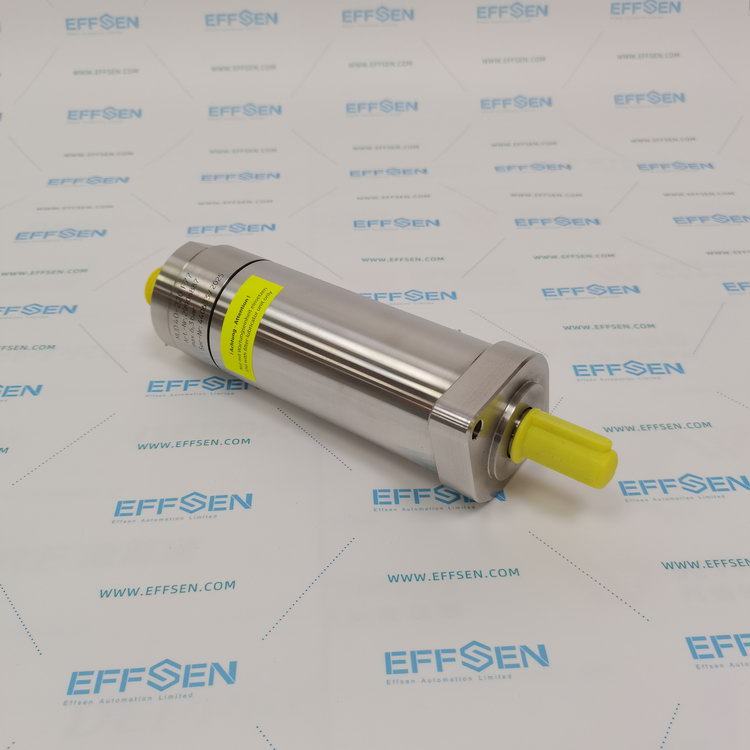

AXXAIR SCOOL-700 Cooler

It is an industrial-grade cutting cooling system designed for metal cutting equipment (such as track saws, pipe cutters, etc.), providing a continuous and stable supply of coolant, effectively reducing cutting temperature, extending tool life, and improving cutting accuracy and efficiency. It is suitable for dry or wet cutting processing scenarios of high-strength materials such as stainless steel, carbon steel, and aluminum alloys.

Core Features

✅ Efficient Cooling & Lubrication

Adopts a high-pressure pumping system to ensure that the coolant evenly covers the cutting area, reducing thermal deformation and tool wear.

Compatible with a variety of coolants (water-soluble oils, special cutting fluids, etc.) to meet the cutting needs of different materials.

✅ Large Capacity & Adjustable Flow

700ml large-capacity coolant tank (or adjusted according to actual capacity) to reduce frequent additions.

Adjustable flow design (such as 50-500ml/min) accurately matches different cutting speeds and tool requirements.

✅ Portable & Easy to Install

Compact and lightweight design, can be integrated into cutting equipment or placed independently, suitable for workshops and field operations.

Quick connection interface, suitable for mainstream brand cutting machines (such as AXXAIR track saw series).

✅ Durable & Low Maintenance

Anti-corrosion material pump body and liquid storage tank, resistant to chemical solvent erosion, extended service life.

Removable filter design to prevent debris clogging, easy maintenance.

Technical parameters

Item Parameters (example)

Model AXXAIR SCOOL-700

Capacity 700ml

Flow range 50-500ml/min (adjustable)

Power supply 24V DC / 220V AC

Applicable equipment AXXAIR track saw, pipe cutter, etc.

Weight XX kg

Material Engineering plastic / stainless steel parts

Typical applications

Metal cutting cooling: wet cutting of stainless steel pipes, carbon steel pipes, and aluminum profiles.

Extended tool life: Reduce high temperature wear of saw blades/knife heads and reduce replacement frequency.

High-precision cutting: Avoid thermal deformation of materials and ensure smooth cuts.