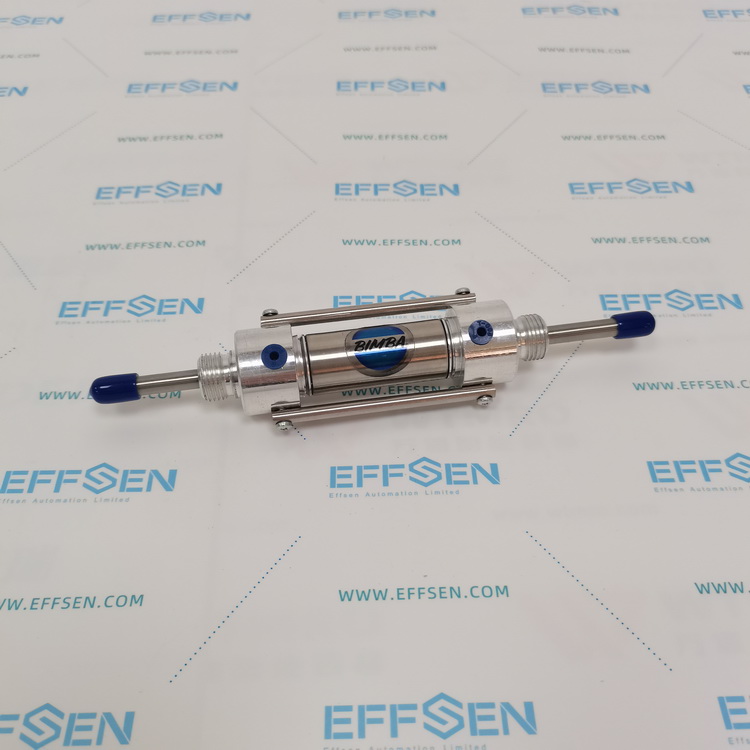

Pimatic P2720R-63/20-250+RA STD+BS+UA Cylinder

Suitable for linear reciprocating motion control in the field of industrial automation. Model P2720R-63/20-250+RA STD+BS+UA represents the specific configuration and functional combination of the cylinder, which has the characteristics of high precision, high stability and modular design, and can meet the needs of various industrial applications.

Model Analysis

P2720R: Cylinder series model, indicating a standard double-acting cylinder.

63: The cylinder bore is 63mm, suitable for medium load scenarios.

20: The piston rod diameter is 20mm, ensuring sufficient strength and stability.

250: The cylinder stroke is 250mm, meeting the needs of long-stroke motion.

+RA: Indicates that the cylinder is equipped with an adjustable buffer (RA), which can effectively absorb motion shock and reduce noise.

STD: Standard configuration, including basic accessories and functions.

BS: The cylinder is equipped with a magnetic switch mounting slot (BS), which is convenient for installing a position sensor to achieve position feedback.

UA: Indicates that the cylinder adopts a universal mounting method (UA), which is compatible with a variety of mounting brackets and fixing methods.

Technical parameters

Working pressure range: usually 0.2~1.0 MPa (please refer to the product manual for details).

Operating speed: adjusted according to load and air supply pressure, up to 1 m/s (theoretical value).

Temperature range: -10°C to +80°C (standard type), suitable for conventional industrial environments.

Sealing material: wear-resistant fluororubber (FPM) seals are used to ensure long-term sealing performance.

Surface treatment: The surface of the cylinder is hard anodized to improve corrosion resistance and wear resistance.