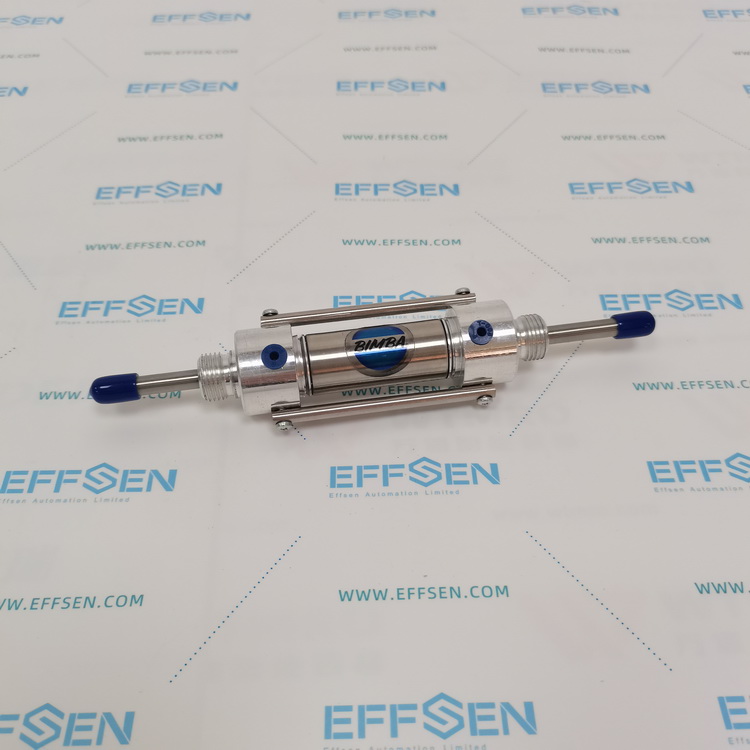

Bimba FSD-310.125-H Square Flat Pneumatic Compact Cylinder

It is a square flat pneumatic compact cylinder produced by Bimba, USA, designed for space-constrained industrial automation applications. The cylinder is made of high-strength stainless steel, with the characteristics of corrosion resistance, high precision and long life. It is widely used in packaging equipment, machine tools, food processing and electronic manufacturing.

Core features

Material and structure

Stainless steel cylinder: Made of 304 or 316 stainless steel, it has strong corrosion resistance and is suitable for harsh environments such as humidity, acid and alkali.

Square flat design: compact square structure, low height, saving installation space, suitable for small workstations.

Performance parameters

Cylinder diameter and stroke: cylinder diameter 31mm, stroke 12.5mm (specific parameters may vary slightly depending on the model).

Working pressure: The standard working pressure range is 0.1-1.0 MPa, and can withstand up to 1.5 MPa.

Temperature range: Working temperature -20°C to +80°C (optional high temperature model, up to +200°C).

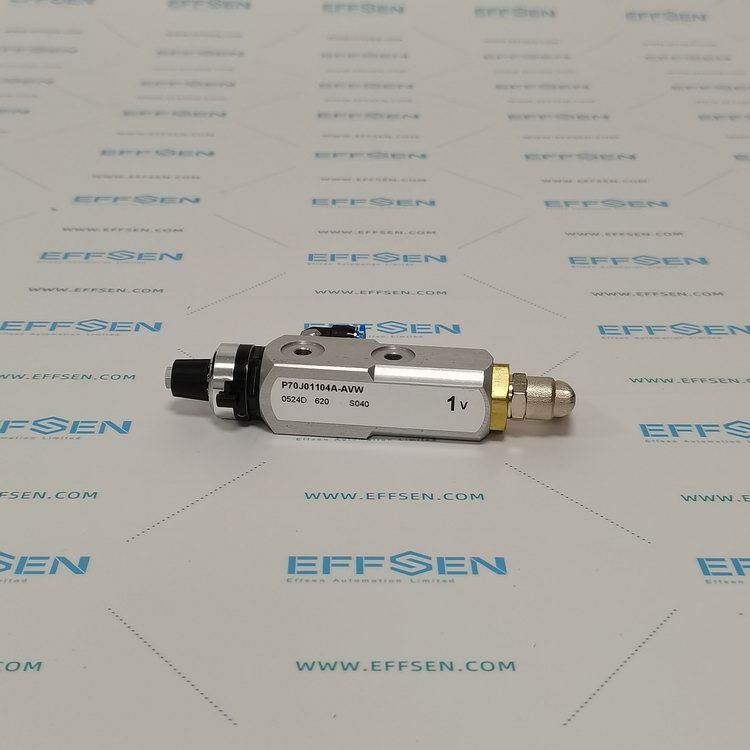

Installation and Configuration

Multiple installation methods: support flange, foot, center axis and other installation methods, flexible adaptation to different equipment.

Inductive switch options: can be configured with magnetic inductive switches, provide position feedback, and facilitate automatic control.

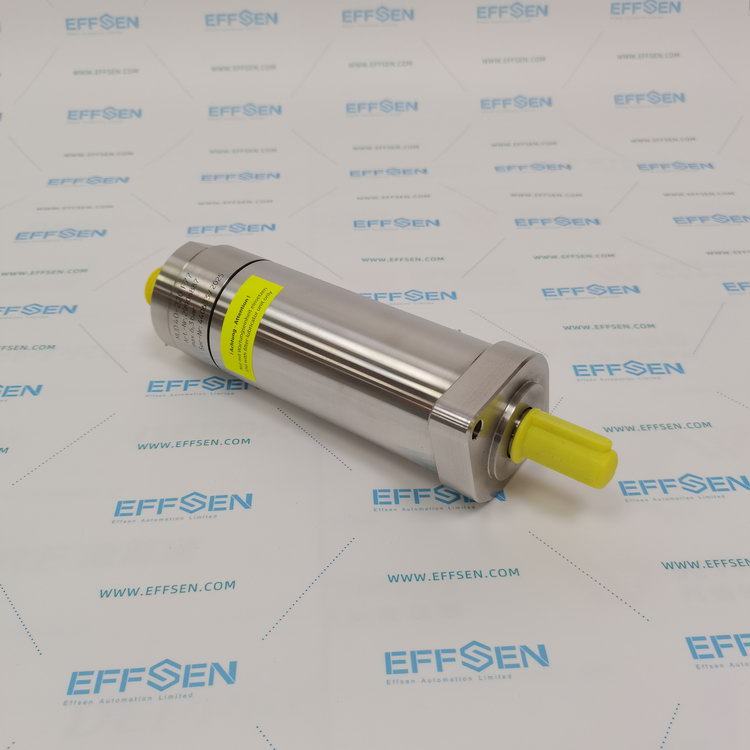

Sealing and lubrication

Double lip seal: high-performance seals are used to ensure no leakage, suitable for vacuum or high-pressure environments.

Self-lubricating design: the piston rod surface is specially treated to reduce lubrication requirements and maintenance costs.

Technical advantages

High precision and stability

Precision machining and high-quality materials ensure that the cylinder can maintain stable performance under high frequency and high load, and the control accuracy can reach micron level.

Long life design

Wear-resistant materials and self-lubricating technology reduce wear, extend service life and reduce replacement frequency.

Easy to integrate

Standardized interfaces and multiple installation methods make it easy to quickly integrate into existing equipment and reduce transformation time.

Global certification

Complies with international standards such as ISO, CE, UL, etc., with reliable quality and suitable for global markets.