Knoll

Knoll Maschinenbau GmbH, founded in 1970 in Bad Saulgau, Germany, has emerged as a global leader in the engineering and manufacturing of high-performance pump systems, filtration solutions, and material handling equipment tailored for industrial applications.

Knoll Maschinenbau GmbH, founded in 1970 in Bad Saulgau, Germany, has emerged as a global leader in the engineering and manufacturing of high-performance pump systems, filtration solutions, and material handling equipment tailored for industrial applications. With a workforce exceeding 1,000 employees, the company specializes in delivering turnkey systems for metalworking, automotive, aerospace, and chemical sectors, integrating cutting-edge technology with robust German engineering standards.

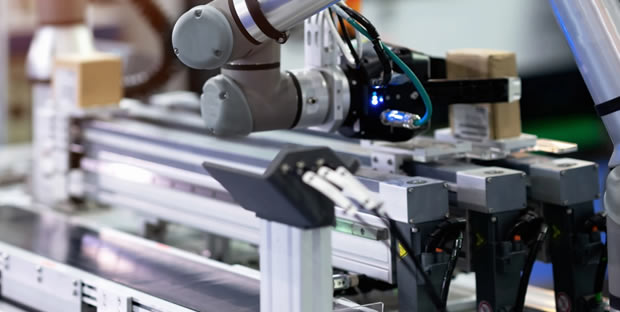

Knoll’s product portfolio is anchored by its advanced pump technologies, particularly its screw pumps and centrifugal pumps. The KTS series screw pumps, renowned for their three-screw design, excel in handling lubricating fluids, high-viscosity media, and abrasive materials with minimal pulsation and mechanical wear. These pumps feature ceramic-lined casings and precision-engineered rotors, enabling operation at pressures up to 200 bar and flow rates exceeding 900 liters per minute. Their self-priming capability and low-noise operation make them ideal for applications such as high-pressure coolant delivery in CNC machines, where they ensure precise lubrication and chip removal during milling and drilling processes.Beyond pumps, Knoll’s filtration systems underscore its commitment to process efficiency and sustainability. The TURBO backflush filter, utilizing centrifugal force and integrated scraper belts, achieves filtration down to 1-3µm without consumables, ensuring consistent coolant quality and reducing disposal costs. The KF-E compact belt filter further extends filtration capabilities, offering continuous operation and low maintenance for fine particle removal in grinding processes. These systems are integral to Knoll’s centralized coolant management solutions, which enable automated coolant recycling, chip evacuation, and real-time monitoring of fluid parameters.Knoll’s material handling lineup includes chip conveyors, shredders, and central coolant filtration systems, designed to streamline waste management and improve machine tool uptime. The company’s modular approach allows seamless integration of pumps, filters, and conveyors into customized systems, tailored to specific plant layouts and production workflows. This flexibility, coupled with Knoll’s emphasis on energy efficiency and IoT-enabled predictive maintenance, positions its solutions at the forefront of Industry 4.0 readiness.

In summary, Knoll Maschinenbau GmbH embodies German engineering excellence, offering a comprehensive suite of pumps, filters, and material handling solutions that redefine industrial fluid management. By combining robust design, cutting-edge technology, and a customer-centric approach, Knoll continues to set industry benchmarks for efficiency, durability, and sustainability in global manufacturing operations.

Disclaimer: Effsen is not an authorized distributor or representative of the products featured on this website. We supply only brand new and original products sourced from reputed or authorized or genuine suppliers. All product names, trademarks, brands and logos used on this site are the property of their respective owners.